Applications of CNC Wood Cutting in Custom Furniture

CNC wood cutting is ideal for creating customized furniture and decorative elements. Companies like Easy Spray utilize CNC technology to manufacture kitchen cabinets, bedroom furniture, office shelves, and even unique decorative features. Whether you're designing a sleek, modern kitchen or elegant dining room furniture, CNC cutting allows for detailed, precision cuts that bring each design to life. Clients can expect a smooth, high-quality finish in every piece, with the added benefit of custom design flexibility.

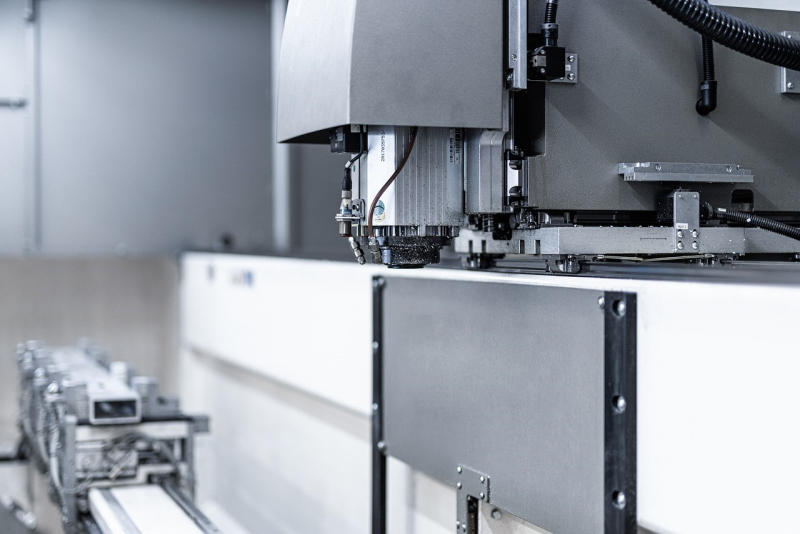

The Future of CNC Woodworking - Precision and Innovation Combined

The combination of advanced CNC machines and skilled craftsmanship offers endless possibilities for unique, high-quality woodworking projects. At Easy Spray, for example, each project is meticulously planned to meet the client's specific needs, ensuring both precision and creativity in every design. As the woodworking industry embraces technology, CNC wood cutting continues to push the boundaries of what can be achieved, providing both efficiency and impeccable craftsmanship.

CNC Wood Cutting vs. Traditional Methods - Why CNC Stands Out

Compared to traditional woodworking techniques, CNC wood cutting offers several key advantages that make it the preferred choice for many manufacturers and craftsmen. Traditional methods rely heavily on manual labor and hand tools, which can lead to inconsistencies in the final product, especially when producing intricate designs or large quantities. In contrast, CNC machines are automated and controlled by computer software, ensuring uniformity and precision with every cut.

Another significant advantage of CNC cutting is the speed and efficiency it brings to the manufacturing process. What could take hours or even days to complete by hand can be done in a fraction of the time with CNC technology. Additionally, because the machine does all the heavy lifting, wear and tear on tools is minimized, reducing the need for frequent maintenance or replacements. This efficiency, combined with the ability to create complex designs, makes CNC cutting a game-changer in the woodworking industry.

By choosing CNC technology, businesses and craftsmen can achieve higher productivity, lower costs, and deliver a superior product to their customers.