The Technological Edge - Secondary Encoders

Secondary encoders represent a significant advancement in industrial robotics. Unlike traditional encoders that rely on a single source of positional data, secondary encoders provide additional feedback, drastically enhancing the precision and rigidity of the robot arm. This dual feedback system allows for real-time adjustments and corrections, ensuring unparalleled accuracy in both additive and subtractive CNC applications. This technology is particularly crucial for industries where meticulous precision is essential.

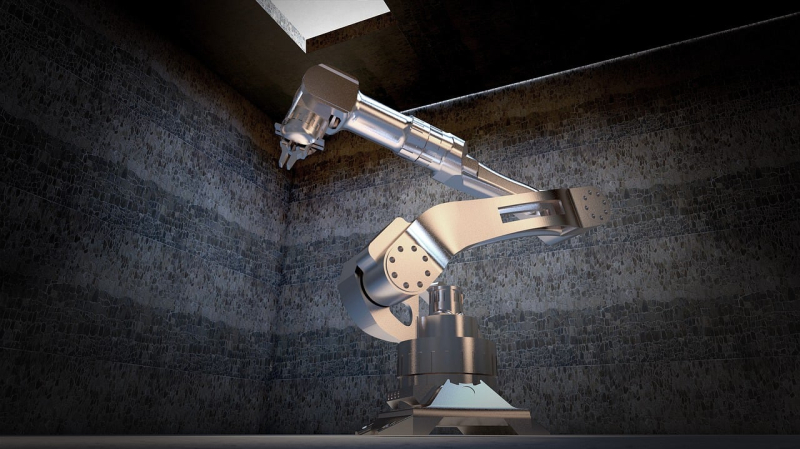

The MAX Series - Precision and Performance Redefined

At the heart of MABI Robotic's product lineup is the MAX series of robots. These robots come in various sizes, each tailored to meet specific industrial needs. The MAX-100-2.25-P, the smallest model in the series, is a testament to MABI's commitment to precision. It boasts an impressive payload capacity of 100 kg and a reach of 2.24 meters, making it perfect for tasks that require exceptional accuracy.

Building on the success of the MAX-100-2.25-P, the MAX-150-2.0-P offers a higher payload capacity of 150 kg and a reach of 2.0 meters, catering to more demanding applications. Both models are continually refined and developed, incorporating valuable feedback from customers to meet a broad spectrum of industrial requirements.

Addressing Industry Needs

The integration of secondary encoders across all axes in MABI Robotic's arms addresses a critical need in industrial manufacturing. Traditional robots often fall short in applications requiring extreme precision due to their single-source feedback systems. MABI's approach not only enhances precision but also increases the overall rigidity of the robotic arm, making it more reliable for high-stakes operations.

MABI Robotic is leading the way in industrial automation, continuously advancing the technology of milling robots. Their commitment to innovation, precision, and performance ensures that manufacturers have the tools they need to achieve superior results. The introduction of secondary encoders across all axes is a testament to their dedication to providing cutting-edge solutions in the world of industrial robotics. As the industry evolves, MABI Robotic's advanced technology ensures they remain the definitive choice for high-precision manufacturing needs.